We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

MANUAL OPERATING UNIT

The manual operating unit allows the machine to be operated in any place imaginable – perfect for manual applications, special applications and maintenance tasks without the control panel, to calibrate the axes and machine.

INTUITIVE OPERATION

The machines are operated via the touch screen or keypad, along with the established workshop-oriented user interface in the familiar design. This offers an override function, which can be used to easily adapt the machining speed.

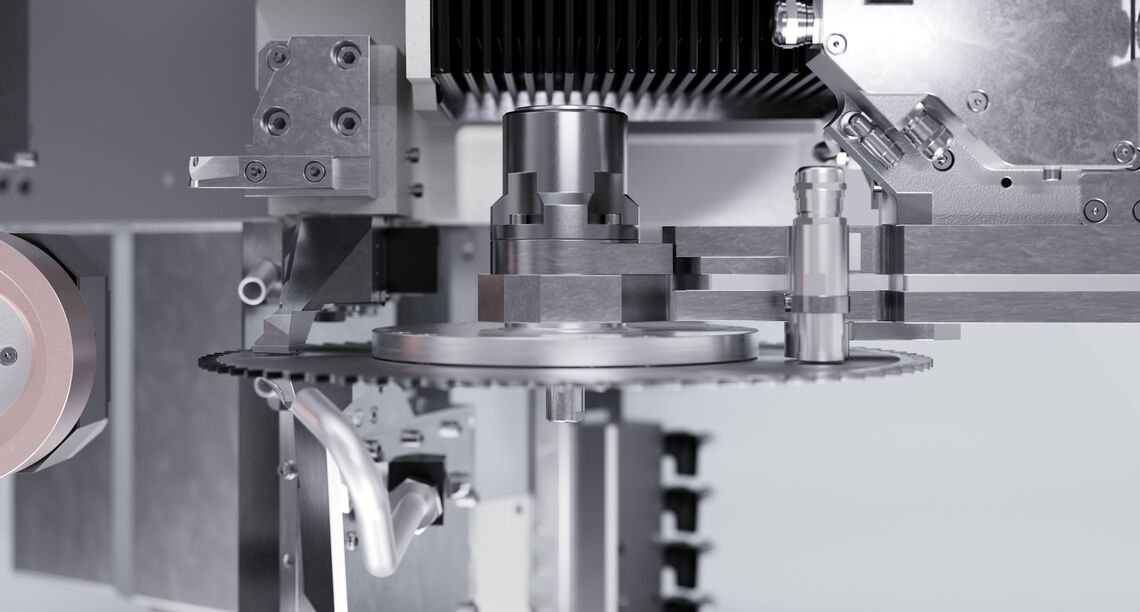

THE MOST ADVANCED DRIVE TECHNOLOGY

Both machines are equipped with powerful servo technology. Energy efficient, spacesaving and easy to service. Designed for complex sequences for shorter machining times and maximum productivity.

coolant return

Thanks to the coolant return flow, no coolant tank – in which dirt could settle – is required. No dirt means no cleaning. Fewer maintenance tasks. More time for what matters most.

IOT GATEWAY AS STANDARD

The keyword is Industry 4.0: Our machines are communication-enabled. An IoT gateway is fitted as standard and this opens the door to the digital world for you.

OPTIMUM ACCESSIBILITY

The control cabinet and the maintenance compartment doors are perfectly accessible and the deep-set operation doors open wide. A sawblade can even be loaded through an open roof with a cran.

MODERN DESIGN

The design is compact and ergonomic, with every detail carefully considered. Perfect for everyday work, maintenance and servicing.

STABLE CONSTRUCTION

Maximum stability, both statically and dynamically, is ensured by the compact monoblock structure made from polymer concrete. Ultimate process accuracy guaranteed.

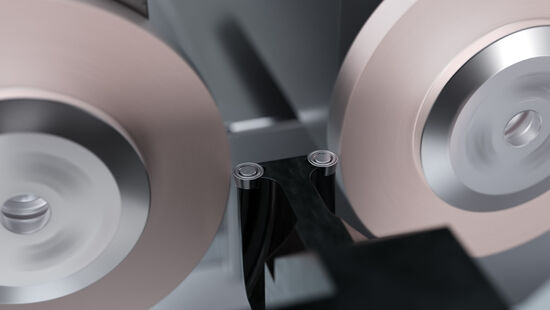

EROSION GENERATOR

The proven and innovative Vpulse EDM erosion generator is the key component of both machines and ensures greater flexibility, higher performance and better surfaces.

The QS 860 and QSF 860 look the same and are almost identical in structure, but are characterised by crucial differences. Both machines are based on the same kinematic concept.

The QS 860 and QSF 860 have been produced to have one goal: To make sharpening your PCD circular saw blades as easy as possible, offering you maximum flexibility with optimised processes so that you achieve outstanding cutting edge surfaces. Fully automated. Powerful. Outstanding quality. Encompassing a broad range of applications. The QS 860 and QSF 860 offer outstanding success when sharpening PCD circular saw blades.

- FULLY CNC-CONTROLLED

The QS 860 and QSF 860 are two fully CNC-controlled machines with 8-axis or 9-axis kinematics. - DIAMETER

Both machines are designed for circular saw blades with a diameter of 80 to 860 mm. - FULLY AUTOMATED SEQUENCES

Both machines feature measuring systems for fully automated set-up and work processes and additional units for specific applications. - FOR TOOL MANUFACTURERS

For everyone producing and supplying PCD circular saw blades. - FOR SHARPENING SERVICES

For service companies that process orders quickly and flexibly. - AUTOMATIC LOADING

For maximum efficiency, up to three machines can be used in conjunction with the VOLLMER ND handling system. - FOR ALL TOOTH GEOMETRIES

All conceivable parameters and machining combinations are possible in one cycle. It doesn't get more flexible than this.

MADE FOR YOU. AND FOR YOUR APPLICATIONS.

- FOR TOOL MANUFACTURERS

For everyone producing and supplying PCD circular saw blades. - FOR END USERS AND SERVICE PROVIDERS

For manufacturers of furniture, floors, panels or insulating materials. - FOR SHARPENING SERVICES

For service companies that process orders quickly and flexibly.

MAXIMUM FLEXIBILITY. FOR ALL APPLICATIONS.

- Processing solid timber

- Further processing of timber

- Processing aluminium and plastic

- Machining composites

- Processing metal

- Processing minerals

HIGHLY FLEXIBLE PROCESSES. OUTSTANDING MACHINING. FULLY AUTOMATED.

Both machines offer two measuring systems, user-friendly dressing cycles and an adjustable opening distance on the blade clamping mechanism make your processes more flexible and improve accuracy – all very simply and automatically.

- MEASURING SENSOR

VOLLMER never comprises on precision. The measuring sensor records all relevant parameters fully automatically and delivers excellent 3D measuring accuracy. Nothing could be more precise. - ADJUSTABLE OPENING DISTANCE ON THE BLADE CLAMPING MECHANISM

The blade clamping mechanism is depressurised during the tooth feed. A wide opening may be required for certain types of saw blade body. Adjusting the opening distance can help increase productivity. - CONTROLLED LATERAL ADJUSTMENT

This enables automatic machining of saws with a clamp in mixed operation. The controlled lateral adjustment turns an 8-axis machine into a 9-axis machine, thereby increasing flexibility.

- CENTRE CLAMP

With the hydraulic centre clamp, saws that are clamped on two flanges can be machined unsupported with manual loading. This may be necessary if a tooth symmetry following the axial run-out is to be achieved. - CENTRE BRAKE

Together with the feed pawl, the centre brake makes it possible to use an opening blade clamping mechanism to machine coated saws. This guarantees perfect positioning.

SOFTWARE

HIGHLY FLEXIBLE PROCESSES. OUTSTANDING MACHINING. FULLY AUTOMATED.

An intelligent, advanced machine concept needs an intelligent, advanced software concept. The QS 860 and QSF 860 make it easy for you. Numerous programs and geometries are already stored.

- AUTOMATIC DETECTION OF REPAIR TEETH

The sensors detect newly inserted teeth and erode these to size. This allows saw blades with newly inserted teeth to be machined in a single set-up.

- AUTOMATIC DETECTION OF BROKEN TEETH

The feed pawl detects broken teeth: This prevents collisions during machining.

- AUTOMATIC DETECTION OF TOOTH PITCH

The feed pawl detects the tooth pitch automatically. No manual entry or setting is required, eliminating the risk of operating errors. Group toothing can also be set up and machined with ease.

- SMART MEASUREMENT PROGRAMS

Depending on the machining operation, specific measurement programs measure with one tooth, several teeth or all the teeth and output the data digitally. This guarantees full quality control.

- ADVANCED MULTI-SURFACE PROGRAM

Thanks to the advanced multi-surface program, up to 90 surfaces can be machined. This can be applied to one tooth or split between up to 30 teeth. This means maximum flexibility for you.

technology database

And that's not all: The integrated technology database makes handling even easier thanks to preconfigured parameters and enhances its user-friendliness, as the right material-specific machining program can be quickly selected. In addition, the technology database can be expanded individually at the customer's request.

OPERATION

SIMPLE OPERATION. WITH TOUCH SCREEN. WITH KEYPAD. THE CHOICE IS YOURS.

First and foremost, the QS 860 and QSF 860 are simple to operate. All the program data required can be found in two clearly structured programming windows. Clear symbols and a modern design ensure clear orientation. The user interface is tried and tested. The touch screen or keypad are used for operation. And for special applications and servicing – for example, for calibration or referencing – the practical manual control is available as an option. Quite simply, it doesn't get easier or more flexible than this. Load, select a program, done.

MODERN DESIGN

Clear symbols, simple operation and a modern aesthetic. Our display is intuitive for any user to navigate.

TOUCH SCREEN AND KEYPAD

Some love keypads, others prefer touch screens. Many use both. The QS 860 and QSF 860 have both. This is not only simple, it is highly practical.

OVERRIDE FUNCTION

The override function acts as a potentiometer, to make speed adjustments in automatic mode as necessary.

TRIED-AND-TESTED USER INTERFACE

Anyone who has already worked with a VOLLMER sharpening machine will already be familiar with this workshop-orientated user interface. Just two programming windows are used for operation.

EROSION ELECTRODE MANAGEMENT

The machines have an identical erosion electrode management system. In other words, once erosion electrodes have been measured, they do not have to be measured again after replacement. This makes handling easier for the operators.

MANUAL OPERATING UNIT

The manual operating unit allows

the machine to be operated in any

place imaginable – perfect for

manual applications, special applications

and maintenance tasks without the

control panel, to calibrate the axes

and machine.

METRIC AND IMPERIAL SYSTEM

Different countries, different units of measurement. Anyone who uses the imperial system rather than metric measurements can find everything in inches here.

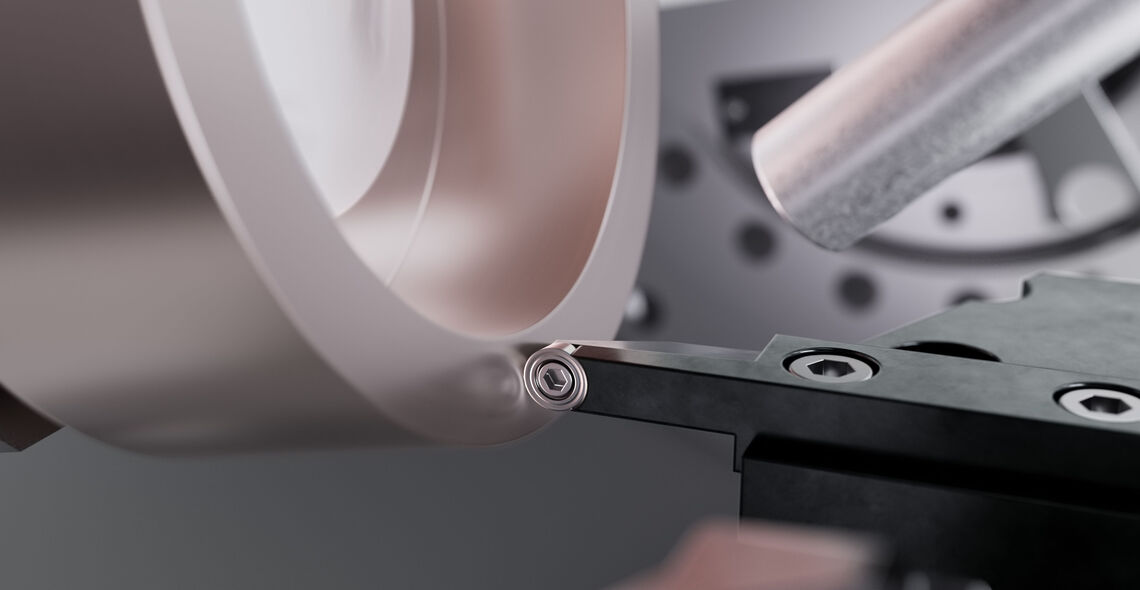

UNIVERSAL FOR TOOTH TOPS.

Greater flexibility: For your sequences too. This is exactly what the QS 860 offers you. A sharpening machine for tooth tops on circular saw blades up to 860 mm. You can enjoy greater flexibility in your programs. You can even combine different sequences across multiple machines.

- CIRCUMFERENTIAL MACHINING ON THE TOOTH TOP

Efficient and flexible machining of various geometries and tooth shapes on the tooth top. - CONTOUR MACHINING ON THE TOOTH TOP

The stand-alone erosion unit enables the machining of a V or radius profile. - AUTOMATIC ANGLE MEASUREMENT

Measuring the clearance angle or bevel grinding angle increases user convenience, for example when machining a profile on the tooth top, and significantly helps to reduce the risk of errors. An external pre-measurement is not necessary.

- TRANSVERSE FEED PAWL

Thanks to the transverse feed pawl of the QS 860 and the associated saw blade mount, even saws with a blade attachment can be machined easily in manual mode. - MEASURING AND DRESSING THE EROSION ELECTRODE

The erosion electrode is subject to wear during erosion. It is therefore necessary to dress it cyclically in order to restore its original properties. With the QS 860, the electrode is automatically measured and dressed. The outcome is perfect erosion results.

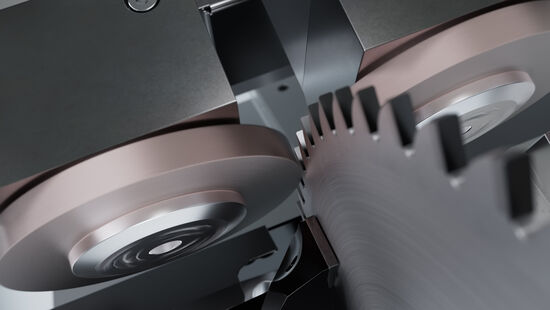

MAXIMUM FLEXIBILITY FOR THE SIDE.

The eight-axis side eroding machine has CNC and is designed for complete machining of a wide variety of tooth shapes. Reliable, safe, flawless. It enables you and your specialist staff to easily adjust the angle, along with fully automated calibration and work processe

- MEASURING SYSTEM

The measuring sensor integrated as standard records all the relevant parameters such as the cutting width or blade thickness and uses these to automatically calibrate the machine. - SIMPLE ANGLE ADJUSTMENT

This ensures easy and reliable calibration of different types of saws with different radial and tangential angles. - REPAIR PROGRAM

The repair program increases the flexibility during servicing, and can also be used for multiple surfaces.

- MANUAL SYMMETRY CORRECTION

Operators can manually change the symmetry of the cutting edges, for example for blades which are not level. - MEASURING AND DRESSING THE EROSION ELECTRODE

The erosion electrode is subject to wear during erosion. It is therefore necessary to dress it cyclically in order to restore its original properties. With the QSF 860, the electrode is automatically measured and dressed. The outcome is perfect erosion results.

THE ND HANDLING SYSTEMS. AUTOMATIC AND POWERFUL.

Whether during servicing, with the user or with the manufacturers – VOLLMER has the right ND handling system for everyone who carries out erosion around the clock. How you set it up depends entirely on your capacities and your needs. Discover all the possibilities.

THE ND 230 | 250 | 270 HANDLING SYSTEMS

FOR UP TO 650 SAW BLADES FROM 100 TO 630 MM.

Thanks to the VOLLMER ND handling systems, all options are open to you to make automatic loading variable. Up to three machines can be combined with up to seven loading carriages. Each loading carriage holds up to 50 saw blades, the entire handling system with its 13 loading positions offers you space for up to 650 saw blades which can be machined automatically – around the clock, 24/7.

THE ND 320 | 340 | 360 HANDLING SYSTEMS

FOR UP TO 550 SAW BLADES FROM 200 TO 840 MM.

For larger, even heavier circular saw blades up to a diameter of 840 mm, there is the ND 320 | 340 | 360 handling systems: Up to three machines can also be installed in the full configuration, in conjunction with up to six loading carriages including 550 saw blades. Particularly robust double grippers allow saw blades weighing up to 11 kg to be changed quickly. One-sided gripper assignment makes it possible to automatically machine saw blades up to a weight of 20 kg.

THE PROCESS ORGANISATION. TOTALLY TAILORED TO YOU.

Tooth top or side – what you work on and when and in what order is entirely up to you. The VOLLMER automation concept gives you free choice to decide what order the machining steps follow, and the order for processing the loading carriages. One batch or several batches are no problem. The diameter, number of teeth and tooth geometries can be changed as needed. This is particularly economical for small quantity batches.

EXTERNAL PROGRAMMING. NOT A PROBLEM.

All jobs can be programmed and executed on an external input station using the DES 400 data entry station. You do not even need to be in the same room. Alternatively, or if required, you can also program the saw blade stack directly on the loading system, in addition to the external data entry station.

THE SEQUENCE

- Set the saw blades down on the loading carriage

- Enter the saw blade data on the data entry station

- Select the planned automatic sequence on the control desk

- Start the automatic program

- If needed, change the transport carriage with machined saw blades during machining – and carry out erosion tasks around the clock

THE NETWORKING CONCEPT. INDUSTRY 4.0 READY.

The networking concept from VOLLMER offers you a multitude of options and advantages to make your processes even more flexible and efficient. With the IoT gateway as a hardware component, the digital world is completely open to you

DNC

To manage programs that have already been written centrally, and to be able to use these across several machines, DNC operation is available, which is operated on the customer's own EDP system.

MACHINE AND PRODUCTION DATA ACQUISITION

Additional security for the entire production process is provided by the functions already implemented in the control for acquiring machine and production data. This enables evaluation of machine utilisation and productivity, as well as the storage of tool data.

DIGITAL REMOTE SERVICE

Simple fault diagnostics and user support through remote access to the user interface.

VOLLMER INSTRUCT

This provides targeted help in the event of a fault or when preparing for future service tasks.

OPERATOR NOTIFICATIONS

Store communication relationships and connect to machine parameters. Receive automated notifications on various devices and display values in a standardised format. Use prefabricated processes or easily create your own flows using the Node-RED open-source system.

STANDARD PROTOCOLS

Standardised interfaces and protocols (e.g. OPC UA, MTConnect) mean that data can be effortlessly exchanged between our machines and your applications.

VOLLMER DASHBOARD

The VOLLMER Dashboard for visualising machine data: Access live detailed machine status information. At any time, from any device, from anywhere in the world. You always maintain an overview of the basic data of your machines and the machine utilisation. And you therefore achieve the highest degree of transparency.

IoT-Gateway

With the IoT gateway as a hardware component, the digital world is completely open to you.

DES 400 DATA ENTRY STATION

The DES 400 enables you to prepare jobs at an external workstation while the machine is running, allowing you to make even more productive use of the machine.

SERVICING AND REPAIR.

The QS 860 and QSF 860 are not just incredibly flexible to use, and simple to operate, they are also particularly practical when it comes to servicing, maintenance and repair. At VOLLMER, we are fully focussed on this aspect during development, to make it hassle-free for you.

All maintenance elements are clearly arranged in one place; the control cabinet, pneumatics and fire extinguishing and coolant systems are easily accessible. And if a component simply needs to be replaced, this can be done quickly and easily.

WEAR AND SPARE PARTS SUPPLY

The use of tried-and-tested VOLLMER components guarantees consistent quality and quick procurement of wear and spare parts.

OPTIMUM ACCESSIBILITY

The control cabinet, pneumatics and fire extinguishing and coolant systems are easily accessible for maintenance tasks. All maintenance elements are grouped in a single location.

AUTOMATIC CENTRAL LUBRICATION

For low-effort maintenance.

PNEUMATICALLY CONTROLLED AUXILIARY FUNCTIONS

No hydraulic system, no oil change, no oil filter replacement, which reduces the maintenance required. This is not only simple, it is much cleaner

IDENTICAL CONSTRUCTION

The access and layout are identical on both machines. This simplifies the maintenance routine and reduces the effort required.

THE MOST ADVANCED SERVO TECHNOLOGY

All machines feature the most advanced servo technology with single cable technology – this is safe and powerful, and saves space and energy.

SIMPLE COMPONENT REPLACEMENT

Control components do not require any preconfiguration. This enables spare parts to be procured quickly and, in the event of a fault, allows easy component replacement with quick detection of faults.

The VOLLMER Filtration System 400 was designed for ultra-fine filtration of cooling oil and dielectric. Solids are separated from the liquid in a filter unit with small filter elements, which leads to an improved surface quality.

And the best thing about it is that the system's minimised energy consumption not only has a positive effect on operating costs, but also contributes to sustainable and cost-efficient filtration. Efficiency and quality, combined in a small footprint – the perfect solution for your requirements.

Your Contact

Orchard Park Ind. Estate

Town Street, Sandiacre

Nottingham NG10 5BP

United Kingdom

Phone: +44 115 9491040

Fax: +44 115 9490042

info-uk@vollmer-group.com