We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

WALL CONCEPT

Very rigid, compact construction with optimal accessibility and overview for the operator.

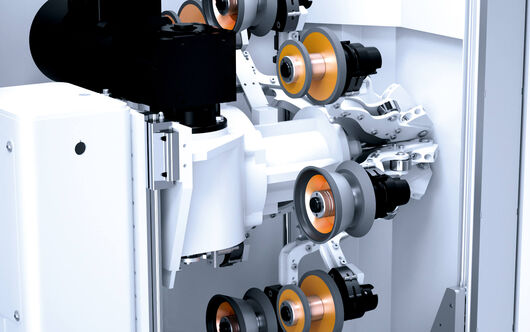

MULTI-LEVEL MACHINING

Two vertical grinding spindles with the grinding wheel set at the C-axis pivot point. Reduced machining times thanks to shorter linear-axis travel distances.

MODERN CONTROL DESK CONCEPT

Height-adjustable, with touchscreen, 19" diagonal screen size and optimum view into the machining chambers.

NUMROTOplus®

The reliable, intuitively operated software with 3D tool and machine simulation, combined with collision monitoring.

GRINDING-WHEEL CHANGER

Provides even more flexibility in your manufacturing processes – with eight HSK-50 grinding wheel sets. Both grinding spindles can be loaded with complete flexibility.

AUTOMATION

Such as with the VOLLMER HP 170 pallet magazine or the HPR 250 free-arm robot for increased capacity and flexibility.

THE GREATEST PRECISION FOR EVEN THE SMALLEST OF TOOLS

Vertical multi-level machining that sets new standards. The precision and efficiency of the VGrind series is now also available for rotationally symmetric solid carbide tools in the 0.3 mm to 12.7 mm range. The VGrind 340S: A five-axis grinding machine that is equipped with all the attributes that modern tool manufacturing requires. And, what's more, there are plenty of intuitive details for the production of small sizes to boot. New linear induction motors on the x, y and z axes provide a clear increase in performance. The result: Even greater precision, for an even better surface quality.

THE APPLICATION

The VGrind 340S was designed to produce carbide drills and milling cutters with a diameter ranging from 0.3 to 12.7 mm. The high flexibility provided by the possibility to change both grinding wheel packages, the reduced changing times thanks to the positively guided system and the meaningful automation options provide the best prerequisites for efficient and high-quality manufacturing.

THE MACHINE CONCEPT

Precision and efficiency squared: This principle is also followed by the VGrind 340S – thanks to two vertically arranged grinding spindles. This principle is complemented by several useful details and options for machining small radii. The result: Maximum perfection at the lowest tolerances.

- Five-axis CNC grinding machine with innovative kinematics

- Two grinding spindles situated one above the other with the grinding wheel set positioned at the C axis pivot point – for ensuring extremely precise grinding results

- The vertical spindle arrangement solves the well-known problems related to fixed and floating bearings

- New wear-free linear induction motors on the X, Y and Z axes not only guarantee lasting consistency of quality and lower maintenance costs, but are also the key to improved surface quality

- Innovative wall concept with the highest possible rigidity and outstanding damping thanks to polymer concrete

- Equipped with a tool steady rest as standard for the best radial run-out quality on the tool, as well as linear scales for even greater precision

- Effective motor and spindle cooling concept for higher thermal stability and lasting power and precision

- Both spindles can be fitted with various different grinding wheel sets. The automation option ensures seamless conversion

- Flexible automation options for loading of carbide tools

- Grinding spindle available with a motor or belt drive

- Automatic changing of grinding wheel sets complete with coolant nozzles for optimum productivity

- Automatic gripper compensation as an in-process solution: Maximum precision when loading and unloading tools and reduction sleeves for decreased wear and optimal radial run-out

- Internal grinding wheel dressing device: For consistently optimal radial and axial run-out

- Wheel probe: Grinding wheel alignment and wear control within the machine

- Automated changing of intermediate sleeves with bayonet

- Automatic sticking unit enables the abrasive coating to be opened during production

Simultaneous grinding wheel package and tool change in combination with the HP 160 pallet magazine for reduced non-productive times during loading

THE OPERATING CONCEPT

In order to be able to exploit the full potential of your VGrind 340S, simple and intuitive operation is a fundamental prerequisite. This begins with the control desk, which is positioned so that not only the LCD display, but also the working area can be always be observed in the best possible manner. Operation via the keyboard or touchscreen allows for precise machining of the tool. The multifunction handwheel ensures even more flexibility: It can be freely positioned on the enclosure and is designed for setting a required axis – without using the control desk. In short: With the VGrind 340S, it becomes a simple pleasure to achieve the best results.

ERGONOMIC OPERATION

- Flexible, height-adjustable and tilting control desk

- Variable multifunction handwheel, optimal machine access

- Easy access to grinding spindles

SOFTWARE NUMROTOplus®

VOLLMER consciously opted for a mature system that is already established on the market. The logically structured interface guarantees intuitive handling. With established programming systems, a huge variety of tools can be manufactured and resharpened. As a result, every detail on individual tools can be altered and adapted to individual needs. Fully informed: Thanks to a perfect 3D diagram of the tool and machine. And with collision monitoring, you can always stay on the safe side.

- Developing

- Simulating

- Monitoring

- Producing

- Trade fairs

- Resharpening

- Documenting

AUTOMATION

One of the key factors in modern tool production is automating the work processes. The VGrind 340S therefore features a range of useful configuration options that allow you to implement large batches of small tools and make your manufacturing processes more precise, quicker and safer.

With the various automation options that are available, the VGrind 340S can be optimally adjusted to your requirements.

- HP 160 pallet magazine with compact pallets and double gripper to guarantee a quick change between short machining times. For the quick supply of up to 900 tools.

- HPR250 free-arm robot: Allows for the automatic machining of tools with various shaft diameters. For increased capacity and even greater flexibility.

Always supply the right grinding wheel – with no manual intervention required: The optimum automation system for eight grinding wheel sets. If required, this can also include the coolant nozzles on both grinding spindles. This is a vital contribution to productivity within your manufacturing process.

Your Contact

Josef-Loroch-Str. 1

69509 Mörlenbach

Germany

Phone: +49 6209 71590

Fax: +49 6209 715938

info@loroch.de