We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

Circular saw blade grinding machines for optimum saw productivity More productive cutting

Professional care and maintenance is the key to effective and productive use of your carbide or high-speed steel circular saw blades.

VOLLMER has a uniquely diverse portfolio of high-performance, advanced grinding machines for sharpening, maintaining or annealing circular saws. For tool production, chipping saw mills or a sharpening service – VOLLMER has the right solution for your specific needs. And there's more to the blades than just grinding them; we also have impressive answers to other important process steps for your circular saw.

Your advantages of VOLLMER sharpening machines for circular saw blades

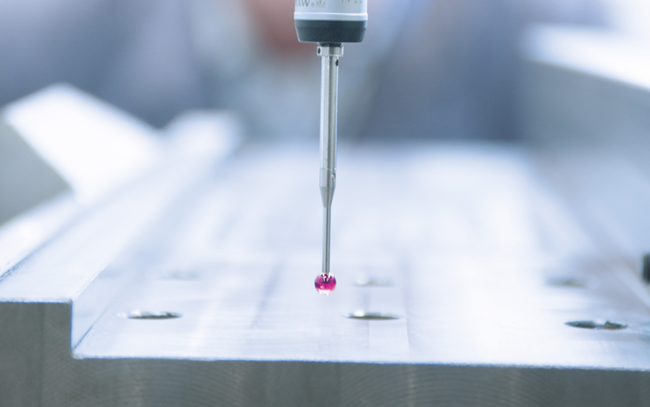

VOLLMER technologies, ranging from manual sharpening machines to handling systems for fully automated complete machining, ensure that circular saw blades are ground to your requirements. The variety of the solutions matches the economic efficiency and quality of your machining process. The VOLLMER sharpening machines for circular saw blades considerably improve your production processes in circular saw machining. With VOLLMER technologies and services, you benefit from:

- High cutting output

- Improved cutting quality

- Longer operating life

- Increased productivity

- Greater operating comfort

Our experts will be happy to help with any questions you may have about VOLLMER circular saw blade grinding machines.

Here we have compiled the most important basic information for you on sharpening tooth faces and tooth tops, side grinding and soldering carbide-tipped circular saws.

Download

Your Contact

Josef-Loroch-Str. 1

69509 Mörlenbach

Germany

Phone: +49 6209 71590

Fax: +49 6209 715938

info@loroch.de