Ihr Browser hat eine andere Sprache als die der aufgerufenen Seite. Diese Seite ist auch in ihrer Sprache verfügbar! Möchten Sie zu der Seite in Ihrer Sprache wechseln?

VOLLMER twin machines erode PCD circular saws automatically 2024-12-04

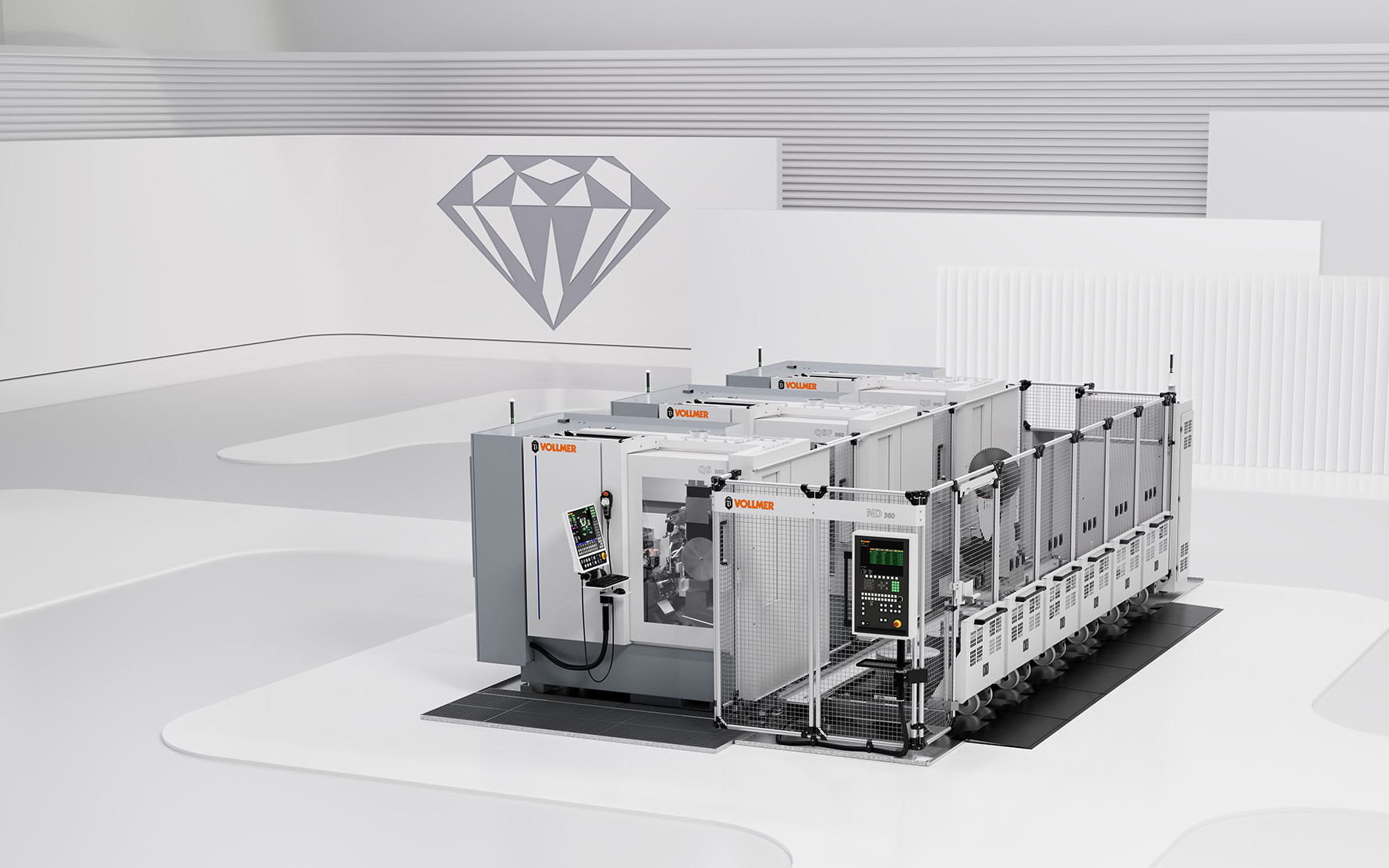

К обзоруFor all that the new QS 860 and QSF 860 disc erosion machine may look the same and have virtually identical construction, they do in fact have some key differences: One twin of the Biberach-based sharpening specialist Vollmer sharpens the flanks of PCD circular saws, while the other twin sharpens the flank flanks. Intuitive control, integrated measuring equipment and handling systems ensure machining is automated. Digitalisation by means of standard IoT gateway, data entry station and DCN operation optimise the erosion processes for the production and maintenance of PCD circular saws.

New erosion machines are called QS 860 and QSF 860

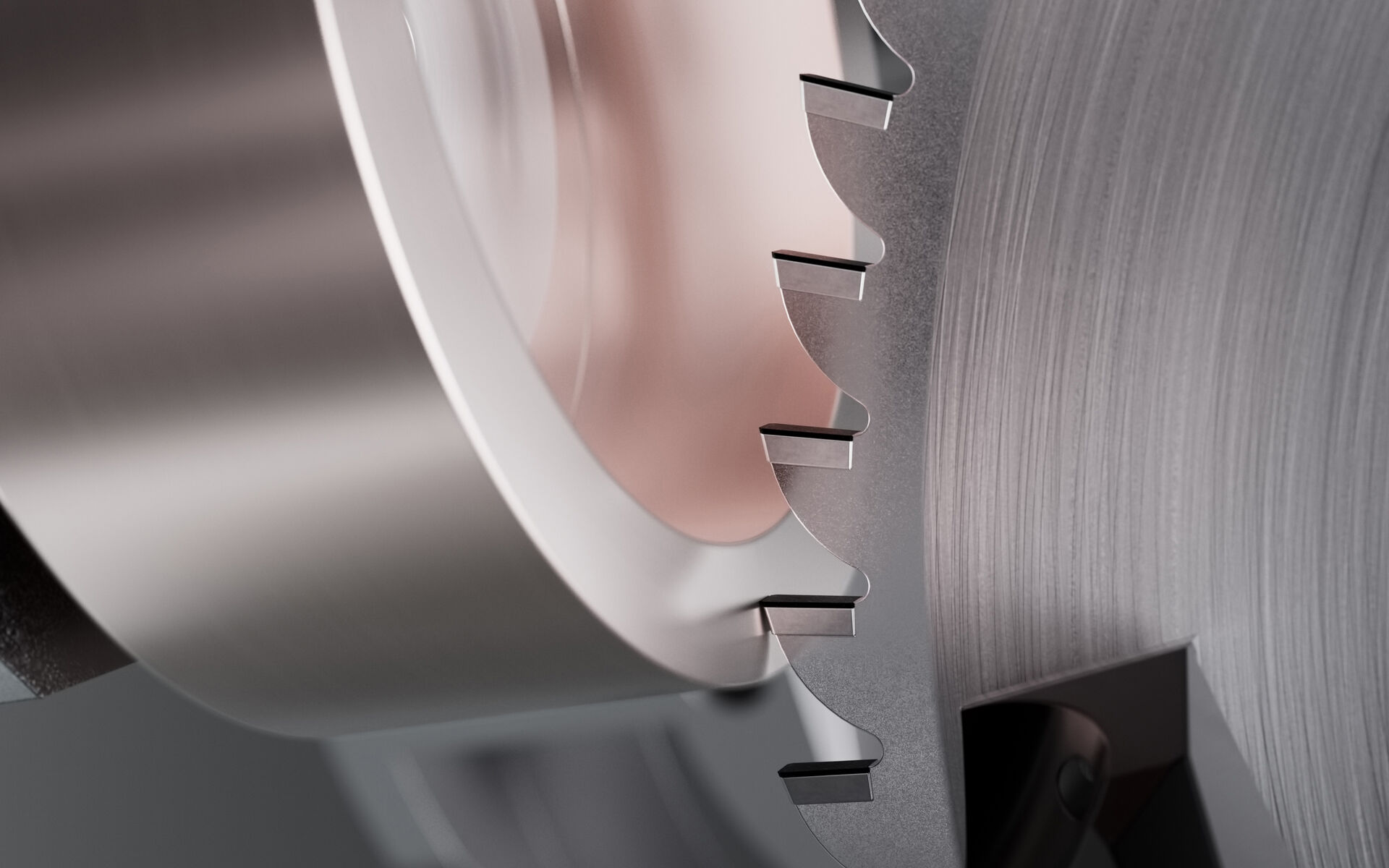

With its hardness rating of ten, diamond really is the king of machining. Circular saws tipped with PCD (polycrystalline diamond) not only achieve long operating lives in wood and metal processing, but are also almost unrivalled when cutting granite, concrete or even highly abrasive composite materials. To ensure that PCD circular saws retain their sharpness, Biberach-based sharpening specialist VOLLMER has launched two new disc erosion machines. With the QS 860 and QSF 860 twins, saw manufacturers can produce their PCD circular saws with different geometries and diameters from 80 to 860 millimetres. On the other hand, sharpening services, furniture manufacturers and insulation producers use the erosion machines to precisely resharpen PCD circular saws that have already been used. VOLLMER ND handling systems, which automatically load up to three machines – with up to 650 PCD circular saw blades depending on the model and specification – ensure unmanned machining around the clock.

The VOLLMER twins have a lot in common

Both machines have a robust design, complete CNC control and measuring equipment for fully automated set-up and work processes. They have measuring sensors that record all relevant parameters and deliver precise 3D measurement accuracy. The sensors detect newly inserted teeth and sharpen these to size. The feed pawls automatically detect broken teeth and determine the tooth pitches so that manual adjustment is not necessary. Thanks to VOLLMER's tried-and-tested operation, users can control and programme the QS 860 and QSF 860 via touch screen or keypad. Since the machines have identical management of the eroding wheels, erosion electrodes that have been measured once do not have to be measured again after they are changed. In addition, worn erosion electrodes are automatically dressed in order to restore their original quality.

In sawtooth machining, every twin is unique

The twins make a difference when eroding the PCD saw tooth - one sharpens its free surfaces, the other its flank free surfaces. The QS 860 erodes tooth faces and tooth tops with different geometries and tooth shapes and automatically measures the relief or bevel grinding angles. This increases ease of operation when machining a profile and contributes significantly to error prevention. The QSF 860 is designed for machining the side angles; it uses an integrated measuring sensor to record all relevant parameters such as cutting width or blade thickness. Different types of saws with different radial and tangential angles are also calibrated automatically.

A unique feature of the QS 860 to date is that a second machining spindle can be used, which can erode contours on the flank face such as concave radii or V-shapes using a peripheral electrode. This machining is carried out in one tool set-up together with the standard free surface machining. This greatly reduces set-up times and increases the quality of the PCD saws, as no reclamping is required.

Digitalisation increases the efficiency of the erosion machines

The twins exchange the recorded operating and machine data via the standard IoT (Internet of Things) gateway in order to determine machine utilisation in real time, for example. A data entry station makes it possible to prepare new orders at an external workstation during operation, thereby making even more productive use of the machine. To centrally manage programs that have already been written, and to be able to use these across all machines, DNC operation is available, which is operated on the customer's own EDP system. The VOLLMER Dashboard visualises machine data live and provides detailed status information about the machine – anywhere in the world, at any time and with any end device.

Контакт со СМИ

Инго ВольфМаркетинговые услуги